Expert Engineers and Detailers

Our team consists of highly skilled structural engineers and detailers with years of experience in creating accurate and detailed shop drawings. We have the expertise to handle complex projects, ensuring the highest level of precision and quality.

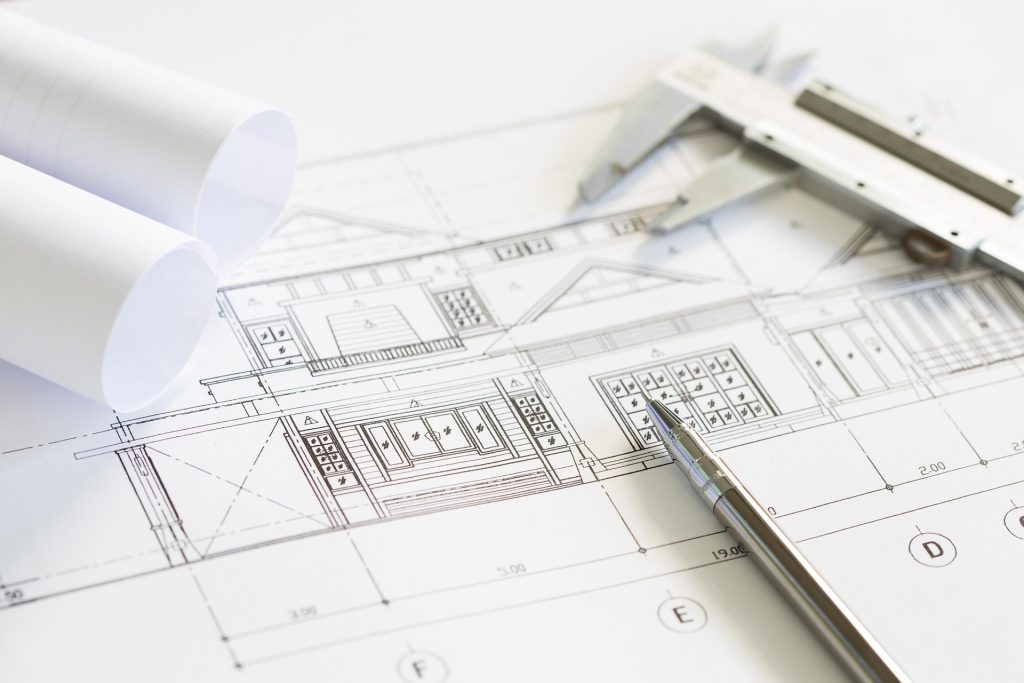

Advanced Software Tools

We use advanced CAD software (such as AutoCAD, Revit, and Tekla Structures) to create precise, 2D and 3D shop drawings that help visualize and plan the structural components of your project. Our tools ensure that we can handle the most complex and intricate designs.

Cost-Effective and Efficient Solutions

Our shop drawing services are designed to minimize errors, reduce rework, and help avoid delays during the construction phase. This results in cost savings and ensures that your project stays on track and within budget.

Customization and Flexibility

We understand that every project is unique, so we tailor our shop drawings to meet your specific needs. Whether it’s a residential building, commercial complex, or large infrastructure project, we adapt our services to fit the requirements of your project.

Coordination and Collaboration

Our collaborative approach ensures that the shop drawings align with the overall design intent and seamlessly integrate with other disciplines, including MEP systems and architectural elements. We coordinate effectively with architects, contractors, and fabricators to ensure a smooth construction process.

High-Quality and Accurate Drawings

Accuracy is at the heart of what we do. Our shop drawings are designed to ensure precise manufacturing, assembly, and installation of all structural elements. This minimizes on-site errors and ensures that the structure is built to specification.

Compliance with Industry Standards

All our shop drawings adhere to the relevant building codes, industry standards, and regulatory requirements. This ensures that your project complies with all necessary safety, quality, and legal standards.

Timely Project Delivery

We understand the importance of meeting deadlines and maintaining project momentum. Our team is committed to providing timely shop drawings, enabling your project to proceed without delays and stay within the desired construction timeline.

Shop drawings play a critical role in the construction process. They serve as the bridge between the design concept (as seen in architectural and engineering drawings) and the actual construction or fabrication of building components. Here’s a breakdown of their basic role:

Shop drawings provide precise details for the fabrication of structural components (e.g., beams, columns, steel framing, concrete panels). They specify

dimensions, materials, reinforcement, and the method of manufacturing, ensuring that each element is created correctly and to specification. These drawings guide fabricators and manufacturers to produce parts that fit together perfectly during the assembly process.

They eliminate ambiguity by offering exact measurements, materials, and construction methods, reducing the risk of mistakes or misunderstandings

during construction. Shop drawings are created with high precision to ensure that the components fit within the overall design, minimizing errors during installation.

Shop drawings include installation instructions that guide how various components will be assembled and installed on-site. They show the sequence of

assembly, proper alignment, and any critical details like connections (e.g., welding, bolting, or anchoring). These drawings help contractors and construction teams efficiently put together the structure while avoiding delays.

Shop drawings are a communication tool that links architects, engineers, fabricators, and contractors. They translate design concepts into actionable

steps for fabrication and construction, ensuring that everyone involved has a clear understanding of the project’s details. They provide an opportunity for coordination between various trades (e.g., structural, mechanical, electrical, plumbing) to ensure compatibility and

avoid clashes.

Shop drawings help clarify the design intent provided in the architectural and structural drawings. By breaking down complex design elements into

manageable details, these drawings ensure that the final product aligns with the original vision. They also allow for the identification and resolution of any conflicts or discrepancies between the design and construction before the work begins, preventing costly rework.

Shop drawings ensure that the components being fabricated meet local building codes, industry standards, and regulatory requirements. They are typically reviewed and approved by engineers or architects to confirm that the designs comply with safety, performance, and quality regulations.

By providing a detailed breakdown of each component, shop drawings minimize the chances of errors during construction. For example, if a beam is incorrectly fabricated or misaligned during installation, it could affect the structural integrity of the entire building. With accurate shop drawings, such errors are significantly reduced, leading to smoother and more efficient construction processes.

Shop drawings are used to identify the exact quantities of materials required for fabrication. This helps with material procurement and budgeting, ensuring that the correct materials are ordered, reducing waste, and preventing costly delays due to missing or incorrect materials. Having precise information also helps maintain the project within the designated budget.

By providing clear, actionable steps, shop drawings help establish realistic timelines for fabrication and installation. Contractors can better plan for each phase of construction, ensuring that the project stays on schedule. The detailed instructions help coordinate delivery and installation of materials in a timely manner, preventing any construction delays.

Shop drawings are not static; they can be revised during construction to account for design changes or field conditions. As-built shop drawings provide a record of any adjustments made to the original design during construction. These documents serve as valuable references for future maintenance or modifications to the structure.

Conclusion:

The basic role of shop drawings is to ensure that all structural elements are fabricated and installed with precision, according to the design specifications, and in compliance with relevant standards. They serve as a vital tool for clear communication, preventing errors, and reducing the risk of rework during the construction process. By providing detailed instructions and clarifying design intent, shop drawings help streamline the entire construction workflow, ensuring the project’s success.

© 2025 SUNRISE RAYS ENGINEERING CONSULTANTS. All Rights Reserved, Powered by MSOFT Technologies.

WhatsApp us